The refining method of rice bran oil refinery plant:Chemical refinery,Physical refinery,Chemical &physical combination refinery

Working process of rice bran oil refinery plant:

1.Pump crude edible oil into refining tank and heat with conduction oil, and the temperature will reach about 70°C-80°C after one hour.

Add acid or alkali to separate according to the acid value. After one hour’s processing and 4-6hours deposit, then convey soap stock to storage tank.

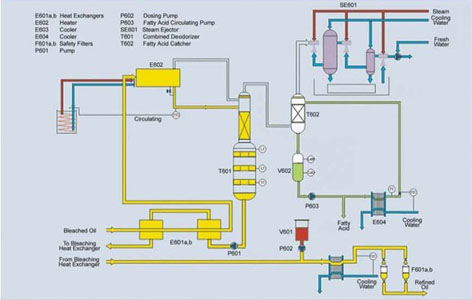

2.Pump refined oil into decoloring tank. When it is up to 90-110°C after one hour’s heating, add clay into tank for 20min’s processing. Then separate clay and oil with filter.(3Put decolorizing oil into deodorization tank with vacuum pump. Heat and process with steam for odor removal. After filtering, you will get final oil product.

The main process of rice bran oil refinery plant:Crude oil,Degumming,Deacidification,Bleaching,Frame filter,Deodorization,Dewaxing,Leaf filter. Rice bran oil refinery plant Main parts:

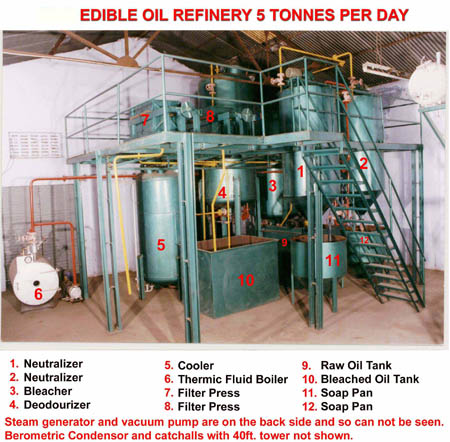

(1) Refining section: used to P-acid de-gumming, alkali refining de-acid and water rinsing.

(2) Decoloring section: used to remove off pigments, bleaching oils and grease dehydrate.

(3) Deodorizing section: to remove off the odor components in oil.

(4) Dewax: used to remove off the wax in the oil, in order to get the high quality oil.

(5) Heat-transfer oil stove: supply each device production needing heat energy, temperature reach above 280°C.

(6) Steam generator: produce the needing steam for de-odoring and distillation.

(7) Vacuum pump: supply needing vacuum for dehydrate, de-color, de-odor. Vacuum degree can reach above 755mm Hg.

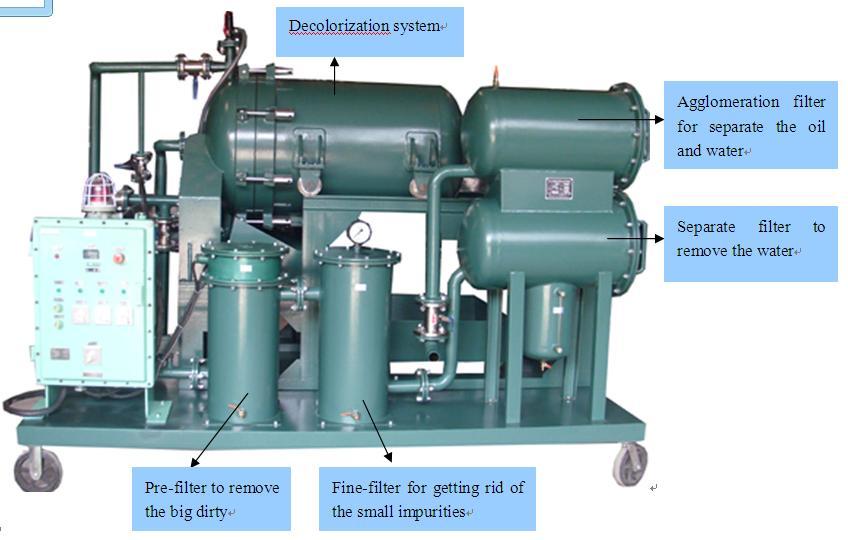

(8) Press filter: filter clay, filter out clear oil.

(9) Air compressor: blow dry bleached clay, blow empty the leftover oil in the press filter.