Edible oil is indispensable in People’s Daily life. In recent years, with the rapid development of global edible oil market, the consumption of edible oil has reached about 30 million tons.

Project Report:10~20 ton/d Small Cooking Oil Production Line

Currently, the establishment of cooking oil processing plant is still a good choice, but a lot of users do not know where to start, how to open the cooking oil processing factory and what the related equpment? These are the issues that entrepreneurs are concerned about. Here in this article ABC Machinery will talk about how to open a cooking oil processing plant. (Hot Product: Mini Mustart Oil Mill Plant )

- 1. What are the requirements for establishing a cooking oil processing plant?

There are two common types of business. One is small oil extraction workshop and the other is to open a regular cooking oil processing factory. Runing a small oil extraction workshop is simple. You just need to rent a room, apply for business license, and then you can undtertake the edible oil making business. While setting up a cooking oil processing factory is more complex. You should have a formal plant, and have the right to use the land, and the produced cooking oil should also meet the natinal edibel oil grade standards. ( Related post: mini soybean oil plant cost in india)

- 2. What equipment does cooking oil processing plant need?

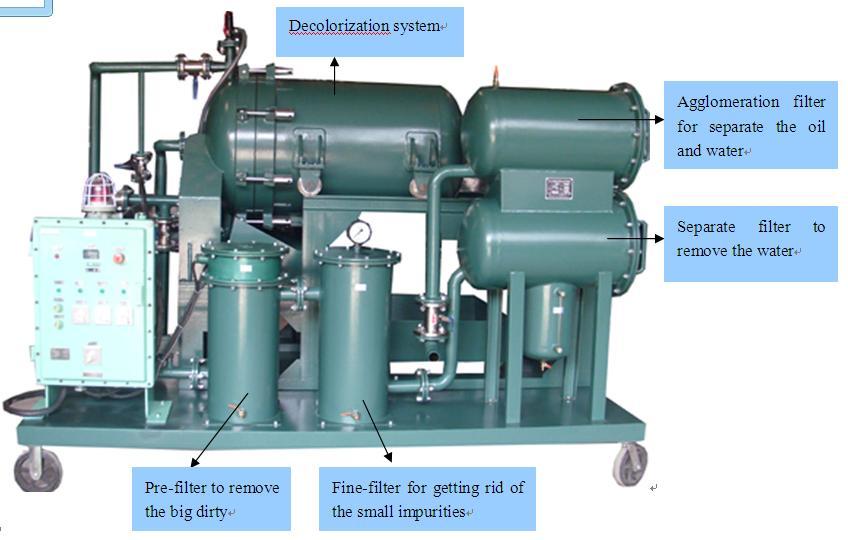

When planning to start a small oil extraction workshop, a screw oil press is OK. If necessary, you can add a set of cooking oil refining equipment. When planning to run a cooking oil factory, you will need a complete set of oilseed processing machinery which includes oilseeds pretreatment machinery, oil extraction machine, oil refining machine and many other auxiliary equipment.

- 3. What should we pay attention to when buying edible oil processing equipment?

The selection of edible oil processing equipment should be based on your needs of production output. How much oilseeds you want to process per day? And what’s the requirement of final oil quality standard? The model and configuration of each equipment should be reasonably selected. Look for some reliable manufacturers of cooking oil processing equipment to do investigating, inspecting, and comparing, so that to choose the better equipment. It is very important to choose the right manufacturer, so that to ensure the equipment quality, process design, reasonable factory layout, low production cost and good service.

Oil filling machines are of different types. This list can include anything from vegetable oil packing, cooking oil filling machine, oil filling machine, lubricant oil filling machine, lube oil filling machine, just to mention but a few. When choosing such a machine for any applications, it is important to consider some various factors when purchasing this one. It is particularly important to take crucial keenness when selecting filling machines for edible oils.

Oil filling machines are of different types. This list can include anything from vegetable oil packing, cooking oil filling machine, oil filling machine, lubricant oil filling machine, lube oil filling machine, just to mention but a few. When choosing such a machine for any applications, it is important to consider some various factors when purchasing this one. It is particularly important to take crucial keenness when selecting filling machines for edible oils. So, what are the factors that one will need to consider when selecting an Essential Oil Extractor? Various methods can be put into place for oil extraction. These can include anything from distillation, maceration, enfleurage, solvent extraction to expression. Selecting the most appropriate extractor to match the best method for your particular type of oil will work best for you since some oils are of the highest quality extracted through certain methods.

So, what are the factors that one will need to consider when selecting an Essential Oil Extractor? Various methods can be put into place for oil extraction. These can include anything from distillation, maceration, enfleurage, solvent extraction to expression. Selecting the most appropriate extractor to match the best method for your particular type of oil will work best for you since some oils are of the highest quality extracted through certain methods.